Security

The security industry involves a range of businesses and organizations that provide products and services aimed at protecting people, property, and information from various threats. This includes physical security measures such as access control, surveillance, and emergency response, as well as cyber security solutions like network protection, data encryption, and threat detection. The industry continues to evolve and innovate in response to emerging risks and new technologies, with a growing emphasis on data privacy and risk management.

Automated manufacturing of security devices – such as surveillance cameras, access control systems, and alarms – involves the use of computer-aided design and manufacturing (CAD/CAM) software to create and test prototypes, followed by automated production line systems to mass-produce the final product. The benefits of automated manufacturing in the security industry include increased efficiency, accuracy, and consistency in the production process. This results in lower costs, faster production times, and higher quality end-products. Additionally, automated manufacturing allows for customization and flexibility in the design and production of security devices to meet specific customer needs.

Anaheim Automation is a leading provider of automation solutions, including motion control systems and motors used in the security industry. Our products are used in surveillance cameras, access control systems, and other security devices, as well as in the machinery in factories where these items are manufactured, to ensure reliable and efficient products. With a focus on quality and innovation, Anaheim Automation continues to play a vital role in helping to keep people and property safe.

Products for Security

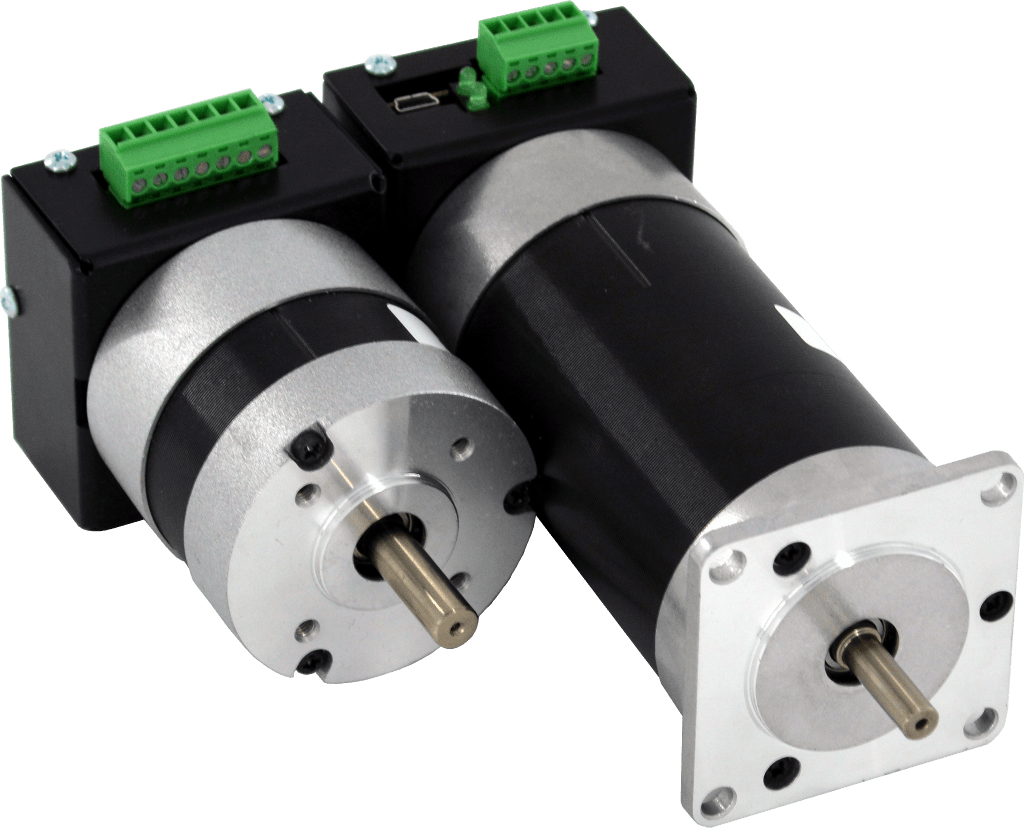

Brushless DC

When it comes to automated security manufacturing and devices, Brushless DC products are a popular choice for a number of reasons. These products offer high efficiency, precise control, and are low-maintenance, making them ideal for use in a wide range of security equipment such as access control systems, surveillance cameras, and automatic gates or doors. Additionally, the smooth and quiet operation provided by BLDC components makes them well-suited for discreet applications in the security industry.

Anaheim Automation offers a variety of Brushless DC Motors to meet the needs of nearly any security application. Our BLDC motors come in multiple body styles and frame sizes ranging from NEMA 09 to NEMA 48, and deliver torque ranging from 0.7 to 90 oz-in. For added protection, our IP65-Sealed Brushless Motors are available in frame sizes from 57mm to 110mm.

Our Brushless Drivers and Controllers are available in enclosed, open-frame, and board-mountable styles, with input voltage ranges of 6 - 50VDC or 85 - 265VAC, peak power up to 2,000 Watts, and peak current up to 100 Amps. Anaheim Automation takes pride in the fact that all of our BLDC motor controllers are manufactured in the USA, with most designed and built in-house.

For applications that require greater torque than what is provided by our standard motors, we offer a selection of BLDC Planetary Gearmotors. These gearmotors consist of a round-bodied BLDC motor (frame sizes from NEMA 09 to NEMA 23) and an integrated planetary gearbox in a number of gear ratios. Peak torque ratings are between 3 and 6,249 oz-in, with speeds ranging from 500 to 15,000RPM. We also carry BLDC Spur Gearmotors, which incorporate either a round-bodied NEMA 23 or square-bodied NEMA 34 brushless motor and a spur gearbox, with peak torque ratings from 694 to 22,500 oz-in and rated speeds from 21 to 1,333RPM.

Our BLDC Linear Actuators with Ball Screws are another excellent solution for security applications that require linear positioning. These compact units integrate a ball screw into a high-powered BLDC motor, with 2mm or 5mm travel options and rated torque up to 15.5 oz-in.

In addition to offering a wide variety of standard BLDC products, Anaheim Automation is committed to meeting the unique needs of our customers. That's why we offer value-added services, such as the addition of a brake, encoder, cable, or connector, as well as more complex customization services such as shaft modifications, special wiring, private labeling, and more. Please note that a Minimum Order Quantity (MOQ) may be required.

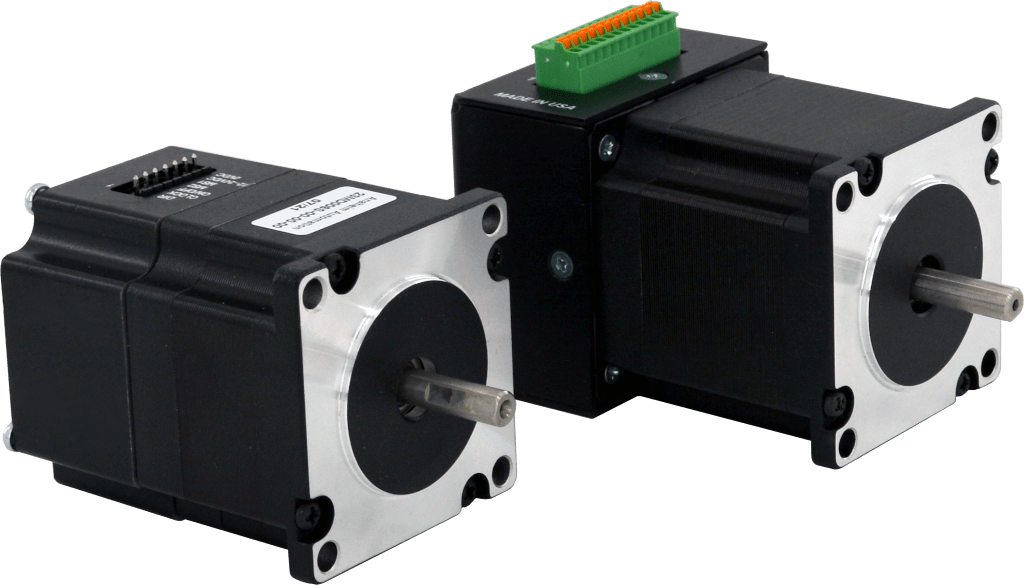

Stepper

Anaheim Automation's high-powered Stepper Products are ideal for meeting the high demands of the security industry. In these applications, the safety and protection of people and property are of utmost importance, which is why our products are engineered to deliver superior performance and accuracy. Stepper motors are designed to move in small, precise increments (steps), which is beneficial for security applications where accurate positioning is crucial. Stepper drivers provide control over the motor's movement and protect the motor from overvoltage, undercurrent, and overheating, which can extend the life of the motor and improve overall system reliability.

Our cost-effective, low-maintenance Stepper Motors offer reliability and consistency. Stepper motors provide a high level of control over speed and positioning, making them suitable for applications that require precise and repeatable motions, such as the movement of surveillance cameras. Customers can choose from a large variety of high-torque square-frame stepping motors in sizes of NEMA 08 to 42, round-frame step motors from NEMA 23 to NEMA 42, and permanent magnet (PM) step motors from 15mm to 57mm in diameter. Additionally, we offer IP65-Rated Sealed Stepper Motors in frame sizes from NEMA 17 to NEMA 42, suitable for harsher environments. These sealed motors prevent ingress from dirt, dust, and debris particles, as well as water from low-pressure jets.

To provide even greater precision and control, we offer a wide range of Stepper Drivers that are compatible with our stepper motors. These drivers allow you to regulate the speed, direction, and torque of the motor. This can contribute to increased efficiency, potentially lowering overall system operation costs. We carry an array of high-performance bipolar, unipolar, and line-powered stepper motor drivers in a variety of voltages, current ratings from 0.2 to 12.5 Amps, and step resolutions. Additionally, we offer a selection of Stepper Controllers and Indexers, as well as Stepper Drivers with Integrated Controllers.

We also offer stepper motors equipped with drivers and controllers for convenient installation and minimal footprint. Our Integrated Stepper Motors are available in NEMA frame sizes 17, 23, and 34. The combined high-torque 1.8° motor with integrated microstep driver provides users with a complete solution, allowing them to simply connect the motor to a power source and a control signal without the need for connecting an external driver or controller. As a result, these integrated motors not only save space, but also reduce the complexity, cost, and time of system integration.

Our Stepper Gearmotors include a stepper motor with an integrated gearbox and are designed to offer high-torque and low-speed capabilities. These gearmotors come in two types: spur gear and planetary gear. Spur Stepper Gearmotors feature a compact and lightweight design with high torque and low noise levels. Planetary Stepper Gearmotors feature a higher torque output, smoother motion, and greater efficiency than their spur gear counterparts. Our stepper gearmotors are available in various motor frame sizes and gear ratios, providing a range of speeds and torque outputs to meet different application requirements.

Customers can also consider our selection of Stepper Linear Actuators, which are an excellent option for converting rotary motion into linear motion. These stepper actuators are ideal for applications that require precise and controlled linear motion, such as opening and closing security gates and doors. They are available in several styles, including Hybrid Stepper Motor Linear Actuators (both external linear and non-captive options), Permanent Magnet (PM) Captive, and PM Non-Captive, with each style providing superior accuracy and repeatability. This allows for precision positioning and motion control. Our stepper actuators are offered with a variety of different strokes, force ratings, and lead screw options to meet a wide range of requirements.

At Anaheim Automation, we understand that security applications require customized solutions to meet unique needs. Therefore, we offer value-added solutions that include brakes, encoders, cables, and connectors, even at small quantities. We can also provide further customizations such as shaft modifications, custom windings, private labeling, voltage matching, and more with a MOQ (Minimum Order Quantity).

Brush DC

Brush DC Motors are commonly used in the security industry due to their high torque output and simple designs. In security applications, they are often used in devices such as security doors and access control systems, where precise and reliable motor control is a crucial factor. Anaheim Automation's line of brushed motors and gearmotors are available in a range of sizes and torque outputs, making them suitable for a variety of security applications. The motors are fully reversible and capable of delivering torque outputs up to 576 oz-in.

Our Brush DC Gearmotors, in particular, offer high precision at an affordable price, making them a popular choice in the security industry. These gearmotors come in several types, including Planetary PMDC (Permanent Magnet DC) Gearmotors, Spur PMDC Gearmotors, High-Torque Spur PMDC Gearmotors, and Worm PMDC Gearmotors. Customers can choose from a broad range of gear ratios to suit their torque requirements.

Custom solutions are also available, allowing for optimization of max speed, torque, and voltage. Modifications to cabling, wiring, connectors, and shafts can also be made upon request, though a minimum order quantity (MOQ) may apply.

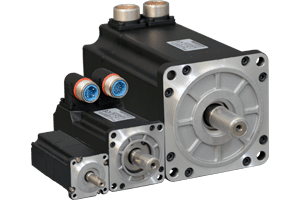

Servo

Anaheim Automation's Servo Products are a great fit for the security industry due to their high performance and ability to provide precise motion control. Our Servo Motors are available in various frame sizes and power ratings, making them suitable for applications ranging from small-scale installations to large security systems. They offer high torque output and can control the movement of multiple processes simultaneously, making them an ideal solution for use in security cameras, alarms, and access control systems. Servo Drives offer excellent position, speed, and torque control, providing high startup torque. Our drives are available in a variety of voltage options and I/O signals, making them easy to integrate into existing systems.

Our all-in-one Servo System packages ensure compatibility and simplify component selection with a motor and matched drive and cables. Choose from single or three-phase options with power up to 5,000 Watts (model dependent). For users with space constraints, Anaheim Automation also offers Servo Motors with Integrated Drives, which combine the power of standard models into a single, convenient package. These integrated units are available in 200, 400, and 750 Watt options.

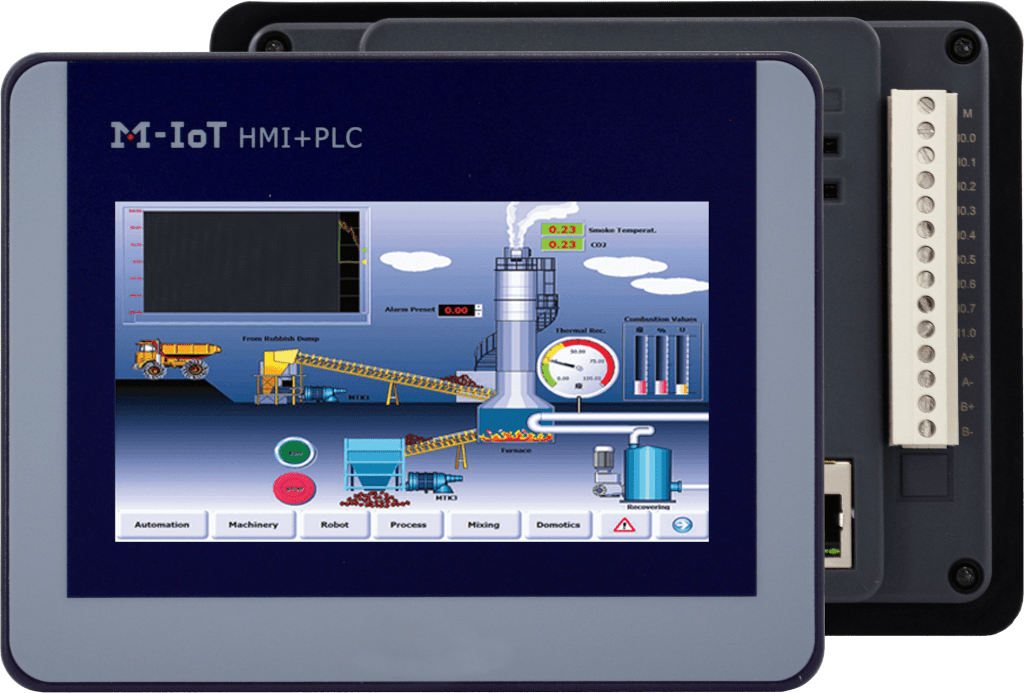

HMI and PLC

The ability to monitor, control, and troubleshoot issues in automated security devices, or in the manufacturing of such equipment, is essential. HMIs (Human Machine Interfaces), or "Industrial Touch Screens," provide a user-friendly graphical interface that allows the operator to interface with the device via a touchscreen. Operators can conveniently control device operations from a single centralized location. With an HMI, it is also possible for users to access the terminal remotely, allowing them to control and monitor the device from a distance. Anaheim Automation's cost-effective HMIs include display screen sizes ranging from 4.3 inches to 15.0 inches and are able to sustain complex, dynamic functions. Multiple programs, displayed on several customizable screens, can be run simultaneously. Specialty HMIs, including Water Resistant and Splash-Proof options, are available in screen sizes of 7", 10.1", and 10.4". For help with selecting the right HMI for your project, our HMI Application Form can help you narrow down the options.

Our HMIs are compatible with a variety of PLC (Programmable Logic Controller) brands, including Siemens, Schneider Electric, Allen Bradley, among many others, making it simple to integrate them into almost any system. Our powerful block-style PLCs in particular are easily connected to our HMIs. Complete our PLC Application Form to determine which unit is right for your application.

Our Integrated HMI/PLC line reduces wiring and footprint by combining the HMI and PLC into a single streamlined package. The 4.3" KNC-HMI-MK043E-20DT and 7.0" KNC-HMI-MK070E-33DT include all of the features of our standalone HMIs and PLCs for unmatched convenience and performance. The HMI runs a 700MHz CPU and includes 128MB Flash + 64MB DDR2 memory storage. A USB Host input is available for additional memory. The integrated PLC supports up to 33 I/O points (model dependent) plus up to eight KS series extension modules for even more I/O points.

Encoders

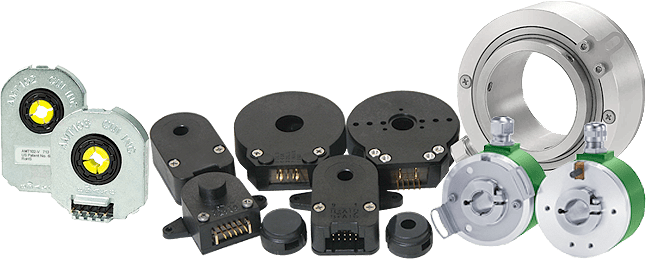

Encoders are essential components in automated security equipment and in the manufacturing of security devices, providing feedback on the position, speed, and direction of components and objects to ensure accuracy and consistency. Anaheim Automation offers various encoder options to serve a wide range of security applications. For example, encoders can be used in automatic gates to measure the position of the gate, ensuring it opens and closes smoothly and securely, and in access control systems, encoders can be used in turnstiles to measure the rotation of the turnstile arm and determine the direction of the movement.

Optical Rotary Encoders are available in single-ended, differential, and high-resolution configurations. These incremental encoders can be mounted to rear motor shafts ranging from 0.59" to 1.0" in diameter, with tracking capabilities up to 200,000 cycles per revolution (CPS) and 32 - 5,000 cycles per revolution (CPR). For a more rugged solution, consider our Magnetic Rotary Encoders, which can be mounted to motor shafts from 0.125" to 1.125" and can track up to 200,000 CPS and 65,536 CPR. A third index channel, open-collector or differential output for U/V/W BLDC motor commutation are also available. IP67-rated Magnetic Linear Encoders are offered in 5, 10, 25, and 50 µm resolutions, with scale lengths up to 100m and rated speeds up to 16m/s. AMT10, AMT11S, and AMT11Q series Capacitive Modular Encoders provide either 12 or 14 Bits of absolute positioning data and 4096 PPR (model dependent) tracking information, and can be mounted to motor shafts up to 8mm in diameter.

Common Applications

Airport Security Whole Body Imagers

Whole Body Imagers – Whole Body Imagers (WBIs) are used by airport security agencies, such as the TSA (Transportation Security Administration), to screen passengers and locate potential threats. The scanner is designed to detect items that may be concealed under clothing without requiring the passenger to remove any clothing items. WBIs utilize either millimeter wave technology or X-rays to create an image of the passenger's body, which is then checked for hidden weapons or other prohibited items.

Products for Whole Body Imagers

Servo Motors and Drives

Servo motors are frequently used in WBIs to control the movement and positioning of the imaging system. In a WBI, the imaging system consists of a gantry that moves over the individual, capturing images from various angles. The gantry is typically controlled by servo motors that are connected to the gantry's various moving components, such as the rotation axis and the linear motion axes. The servo motor receives signals from the drive that specify the desired position and movement of the gantry. The motors use feedback sensors/encoders to ensure that the gantry moves precisely to the desired location and maintains its position during the imaging process. The use of servos in WBIs provides precise and accurate positioning of the imaging system, which is critical for obtaining high-quality images and minimizing the time that the individual must remain in the scanner.

HMIs and PLCs

HMIs and PLCs are used to control and monitor the operation of the WBI system. The operator can use the HMI to start and stop the system, monitor its status, and adjust various settings. The HMI displays a graphical representation of the system, including any sensors, cameras, and other components. PLCs are used to control the various components of the WBI system, including the x-ray scanner and other sensors. The PLC receives input from the sensors and uses that information to determine how the system should operate. For example, the PLC might determine whether an object is a threat or not based on the x-ray image, and then inform the HMI to notify the operator by presenting an alert icon on its screen.

Automated Gates and Doors

Automated Gates and Doors – Automated gates and doors are widely used in the security industry to enhance physical security and control access to, or within, a location. These systems can be programmed to allow only authorized personnel or vehicles to enter the premises, and can be integrated with security cameras and intercom systems for added security, eliminating the need for manual entry and exit procedures. They can be used in a variety of settings, including residential, commercial, and industrial properties, and can be customized to meet specific security requirements.

Products for Automated Gates and Doors

Brush DC Motors and Speed Controllers

Brushed motors and controllers provide efficient and reliable motion control to automatic gates and doors used in the security industry. These motors are simple, reliable, and cost-effective, and can be used to power the opening and closing mechanism of the gate or door. A speed controller is used in conjunction with the brush DC motor to control speed and direction. These controllers receive signals from sensors, encoders, or other input devices to determine the position of the gate/door and adjust the motor speed accordingly. For instance, if the gate or door needs to be opened quickly to allow a vehicle or individual to pass through, the speed controller will increase the speed of the motor to accommodate this.

BLDC Motors and Controllers

Compared to brush DC components, brushless motors and controllers offer greater efficiency and require less power to achieve the same level of performance, which translates into lower energy costs and reduces the risk of overheating or damaging the motor due to excessive heat. BLDC motors also require less maintenance and have a longer lifespan than brushed motors, as brushless motors do not contain brushes that will wear out over time. Additionally, brushless DC controllers provide greater precision in controlling motor speed and torque. They use electronic commutation to control the motor, providing smoother and more accurate motor control, resulting in smoother and more consistent operation of the gate or door.

Automated Surveillance Cameras

Automated Surveillance Cameras – Automated surveillance cameras are a cornerstone of the security industry. They are used to monitor and record activity in various settings, including public spaces, businesses, and residential properties. These cameras are capable of detecting and tracking suspicious behavior, providing real-time alerts to security personnel or homeowners, and recording footage for later review. Advanced features may include high-definition audio and video recording, night vision, motion detection, remote access, mobile alerts, two-way audio, and cloud storage capabilities. Some cameras may even utilize facial recognition technology or the ability to automatically distinguish between people, pets, and other objects.

Products for Surveillance Cameras

Stepper Motors

Stepper motors are commonly used in automated surveillance and security cameras to control the movement and positioning of the camera and its lens. In a typical setup, the stepper motor is connected to the camera's pan/tilt mechanism, which allows the camera to rotate and tilt in different directions. The stepper's precise incremental movements are ideal for accurately positioning the camera so that it can surveil a wide area or track specific movements, such as a person walking across the camera's field of view. Stepper motors have the advantage of being able to hold their position without the need for continuous power, which is important for cameras which may need to remain in a specific position for extended periods.

Encoders

Encoders are frequently used in security camera applications to provide accurate feedback on the position and movement of the camera's lens. The encoder is connected to the motor which controls the camera's pan/tilt mechanism. The encoder uses a sensor to detect the rotation of the motor shaft and sends this information back to a computer, driver, or controller, which uses the data to determine the exact position of the camera. This feedback is critical for accurate positioning of the camera and for tracking movements within the camera's field of view. With an encoder, the system can ensure that the camera is positioned exactly where it needs to be and that any movements are precisely tracked.